Overview

- Brief Narrative

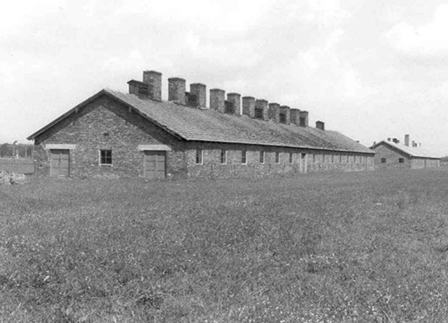

- Wooden box, insert and welding torch tips acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

- Date

-

acquired:

1945 April-1945 July 05

- Geography

-

acquired:

Dora (concentration camp);

Nordhausen (Thuringia, Germany)

- Credit Line

- United States Holocaust Memorial Museum Collection, Gift of Dave Johnson and the Boone Family

- Markings

- a:

side, stamped : HR2

side, stamped : 12/25

b:

side, stamped : 12

side, stamped : 25

c:

side, stamped : HR3

side, stamped : 25/100

d:

side, stamped : 25

side, stamped : 40

e:

side, stamped : 3

side, stamped : 12

f:

side, stamped : Atm

side, stamped : HS / 5

side, stamped : 65

side, stamped : 100

side, stamped : 5

side, stamped : 7

g:

side, stamped : 12

side, stamped : 25

h:

side, stamped : Atm

side, stamped : HS / 7

side, stamped : 150

side, stamped : 220

side, stamped : 8

side, stamped : 10

i:

side, stamped : 40

side, stamped : 65

j:

side, stamped : Atm

side, stamped : HS / 6

side, stamped : 100

side, stamped : 150

side, stamped : 6

side, stamped : 8

k:

side, stamped : Atm

side, stamped : HS / 3

side, stamped : 25

side, stamped : 40

side, stamped : 3

side, stamped : 4

l:

side, stamped : 3

side, stamped : 12

m:

side, stamped : 65

side, stamped : 100

n:

side, stamped : 25

side, stamped : 40

o:

inside lid, above chart, printed, black ink : Sauerstoffdruck der Schneidbrenner u. Schneideinsätze Mod. „HR“ [Cutting torches oxygen pressure "HR" cutting inserts]

inside lid, row 1, printed, black ink : Heizgeräten / HR. 1 / 3-12 / Hr. 2 /12-25 / HR. 3 / 25-100 mm / HR. 4 / 100-300 mm

inside lid, row 2, printed, black ink : Schneidedüsen / HS. 1 / HS. 2 / HS. 3 / HS. 4 / HS. 5 / HS. 6 / HS. 7 / HS. 8 [Cutting nozzles]

inside lid, row 3, printed, black ink : Eisenstärke mm / 3-12 / 12-25 / 25-40 / 40-65 / 65- 100 / 100-150 / 150- 220 / 220-300 [Iron thickness mm]

inside lid, row 4, printed, black ink : Sauerstoffdruck /Atm. / 2-3 / 2-4 / 3-4 / 4-6 / 5-7 / 6-8 / 8-10 / 10-12 [Oxygen pressure atm]

inside lid, below chart, printed, black ink : Diese Angaben sind auf die einzelnen Düsen aufgeschlagen. [This information is based on the individual nozzles] - Contributor

-

Previous owner:

Chester C. Boone Jr.

Subject: Chester C. Boone Jr.

- Biography

-

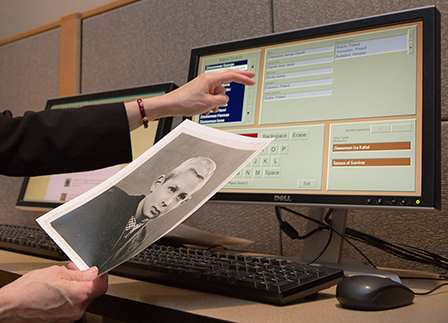

Chester C. “Jack” Boone Jr. (1920-2008) was born in Las Animas, Colorado, to Chester C. Boone Sr. and Venus (Phillips) Boone. Chester had two brothers and four sisters. The family moved to Peru, Kansas when Chester was three, and then returned to Colorado a few years later, settling in Pueblo. Chester graduated from high school in 1940. After high school, he moved to San Diego, California, and worked at Consolidated Air Craft until 1943, when he joined the Merchant Marines. In 1944, Chester entered the United States Army and served in the Army Transport System (ATS), where skills he learned in his family’s machine shop were put to use. Chester was promoted to Second Lieutenant and received training as an amphibious engineer at an Air Force training center. He entered active duty on February 21, 1944, and served in the European Theater, under General Omar Bradley. He maintained the mechanics of a ship that transported troops, north of Omaha Beach, prior to the D-Day assault on June 6, 1944. In spring 1945, Boone was put in charge of the army detachment that took over the underground V-1 and V-2 rocket factory outside of Nordhausen, Germany.

Upon his arrival at Nordhausen in April 1945, Chester saw piles of slave laborers’ bodies the Nazis had enclosed in barbed wire and massacred. A forced labor camp of 6,000 people was attached to the factory, and accessed by a blacktop path, lined with barbed wire. When the inmates were freed by the US troops, few people left, because they had nowhere to go. The underground factory was not discovered by US forces until the war was almost over. It was built under a mountain, and consisted of two mile-long, parallel tunnels that stretched from one end of the mountain to the other, with cross tunnels between them. The tunnels were equipped with lights and railroad tracks. Train cars were loaded with raw materials and slave laborers assembled the rockets, as the cars moved down the tracks. When Chester arrived, there were 120 V-2 rockets present in the factory.

Chester’s detachment was charged with securing and dismantling the factory. However, after six months of work, little progress had been made. While stationed at Nordhausen, Chester often served as a tour guide for visiting G-2 Intelligence officials from Washington DC, including Werner von Braun, the father of German rocketry. When Germany was divided between the Allied Powers in 1945, the factory was in Soviet territory, so Boone’s detachment left. Before leaving, they were able to remove all of the rockets from the factory. However they were unable to completely dismantle the factory.

In 1946, Chester withdrew from active service. He was honorably discharged in 1952, and awarded two Bronze Battle Stars for his service. Chester later moved to Chase, Kansas, where he operated a welding shop for a number of years. In 1953, he moved to Fort Morgan, Colorado, where he opened an oilfield welding shop. Chester married Gloryann Frasco on June 26, 1955, in Fort Morgan and they had two daughters, Kim and Diane. He worked in his shop until ill health forced his retirement in 1990.

Physical Details

- Language

- German

- Classification

-

Tools and Equipment

- Category

-

Equipment

- Object Type

-

Oxyacetylene torches (aat)

- Genre/Form

- Welding.

- Physical Description

- a:

Metal, dark copper-colored welding tip. The base is cylindrical and threaded on the exterior, and the central band is shaped like a hexagonal nut with six flat sides. A conical nozzle, smaller than the central band, extends upward and tapers to a flat tip with a small, centered hole.

b:

Metal, dark copper-colored welding tip. The base is cylindrical and threaded on the exterior, and the central band is shaped like a hexagonal nut with six flat sides. A conical nozzle, smaller than the central band, extends upward and tapers to a flat tip with a small, centered hole.

c:

Metal, dark copper-colored welding tip. The base is cylindrical and threaded on the exterior, and the central band is shaped like a hexagonal nut with six flat sides. A conical nozzle, smaller than the central band, extends upward and tapers to a flat tip with a small, centered hole.

d:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

e:

Small, metal, dark brass-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

f:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

g:

Small, metal, bronze-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

h:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

i:

Small, metal, bronze-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

j:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

k:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

l:

Metal, dark copper-colored welding tip. The base is cylindrical and threaded on the exterior, and the central band is shaped like a hexagonal nut with six flat sides. A conical nozzle, smaller than the central band, extends upward and tapers to a flat tip with a small, centered hole.

m:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

n:

Small, metal, copper-colored welding tip. The base is cylindrical and threaded on the exterior. It has a short neck that extends up and widens into the center section, which is shaped like a hexagonal nut with six, flat sides. A conical nozzle extends upward and tapers to a narrow tube with a small hole.

o:

Rectangular, brown wooden box with a hinged, clamshell lid and box joints at the corners. Centered on the front of the box is a black lock comprised of two metal plates, one nailed to the base and the other nailed to the lid. They are connected by a small, pivoting arm, which locks in place. The lid is secured on the back by two, continuous butterfly hinges nailed to the inner edges. The interior of the box holds a removable wooden insert (p). Adhered to the underside of the lid is a rectangular paper label with German text and a number table printed on it in black ink.

p:

Stepped, rectangular, brown wooden insert from a wooden box (o). The top step has a row of eight, small diameter circular holes cut into it, while the bottom step has a row of four, large diameter circular holes cut into it. There are dark dirt stains on the bottom, and a small, vertical pencil line on the left side of the lower step. - Dimensions

- m: Height: 1.125 inches (2.858 cm) | Width: 0.500 inches (1.27 cm) | Depth: 0.500 inches (1.27 cm)

n: Height: 1.125 inches (2.858 cm) | Width: 0.500 inches (1.27 cm) | Depth: 0.500 inches (1.27 cm)

o: Height: 2.000 inches (5.08 cm) | Width: 5.375 inches (13.653 cm) | Depth: 2.500 inches (6.35 cm)

p: Height: 1.000 inches (2.54 cm) | Width: 4.625 inches (11.748 cm) | Depth: 1.750 inches (4.445 cm) - Materials

- a : metal

b : metal

c : metal

d : metal

e : metal

f : metal

g : metal

h : metal

i : metal

j : metal

k : metal

l : metal

m : metal

n : metal

o : wood, metal, paper, ink, adhesive

p : wood, graphite

Rights & Restrictions

- Conditions on Access

- No restrictions on access

- Conditions on Use

- No restrictions on use

Keywords & Subjects

- Topical Term

- Germany--History--Allied occupation, 1945-1955. Rocketry--Germany--History--20th century. Soldiers--United States. United States. Army--Officers. V-2 rocket. World War, 1939-1945--Campaigns--Western Front.

- Geographic Name

- Nordhausen (Thuringia, Germany)

- Corporate Name

- Dora (concentration camp)

Administrative Notes

- Legal Status

- Permanent Collection

- Provenance

- The welding torch set was donated to the United States Holocaust Memorial Museum in 2007 by the Boone family, and Dave Johnson.

- Record last modified:

- 2022-07-28 18:31:54

- This page:

- https://collections.ushmm.org/search/catalog/irn35744

Download & Licensing

In-Person Research

- By Appointment

- Request 21 Days in Advance of Visit

- Plan a Research Visit

- Request to See This Object

Contact Us

Also in Chester C. Boone collection

The collection consists of two welding torches and associated parts related to the experiences of Chester C. "Jack” Boone of the United States Army at the Dora Mittelbau V2 rocket factory during and after World War II.

Date: 1945

Oxyacetylene welding torch handle with heating tip from the Dora Mittelbau V2 factory

Object

Oxyacetylene welding torch handle with heating tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch handle with cutting tip from the Dora Mittelbau V2 factory

Object

Oxyacetylene welding torch handle with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch handle with cutting tip from the Dora Mittelbau V2 factory

Object

Oxyacetylene welding torch handle with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch handle with cutting tip from the Dora Mittelbau V2 factory

Object

Oxyacetylene welding torch handle with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch handle with cutting tip from the Dora Mittelbau V2 factory

Object

Oxyacetylene welding torch handle with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Welding torch coupling from the Dora Mittelbau V2 factory

Object

Welding torch coupling acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Welding torch cap from the Dora Mittelbau V2 factory

Object

Welding torch cap acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Welding torch cap from the Dora Mittelbau V2 factory

Object

Welding torch cap acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.

Oxyacetylene welding torch neck with cutting tip from the Dora Mittelbau V2 factory

Object

Welding torch neck with cutting tip, acquired by Chester C. Boone at the Dora Mittelbau V2 rocket factory and concentration camp in Nordhausen, Germany, in 1945. The Dora-Mittelbau camp was originally a subcamp of Buchenwald. Allied air raids on German industrial complexes pushed Nazi authorities to use concentration camp prisoners to construct underground tunnels to house factories and development facilities for the V-2 missile program and other experimental weapons. In October 1944, the SS made Dora-Mittelbau an independent concentration camp with more than 30 subcamps of its own. The secret, underground portion of the factory complex was operated by using a slave labor force of concentration camp prisoners. The prisoners were forced to construct the rockets along an improvised assembly line made of railroad tracks. The mortality rate was higher than at most other concentration camps. Many of the prisoners were massacred by the Germans as they camp was evacuated in the spring of 1945. The camp was liberated by American forces in April. Chester Boone was a 2nd Lieutenant in the United States Army detachment that took command of the factory after the liberation. Chester’s group oversaw the removal of the 120 remaining V-2 rockets and the preliminary dismantling of the factory for six months, until it came under Soviet control, with the postwar partition of Germany between allied forces.